One of the most overlooked functions of a wood stove is heating water. A few decades ago many wood stoves (especially cook stoves) used what was called a hot water front (small tank in the woodstove) in conjunction with a range boiler (large water tank) beside/behind the wood stove to produce endless hot water.

The hot water front (which is nothing more than a small tank with an inlet and an outlet) was placed in the firebox of the stove and the tank was connected by copper, steel, stainless steel, brass, or cast iron piping. None of these systems required pumps or fancy controls.

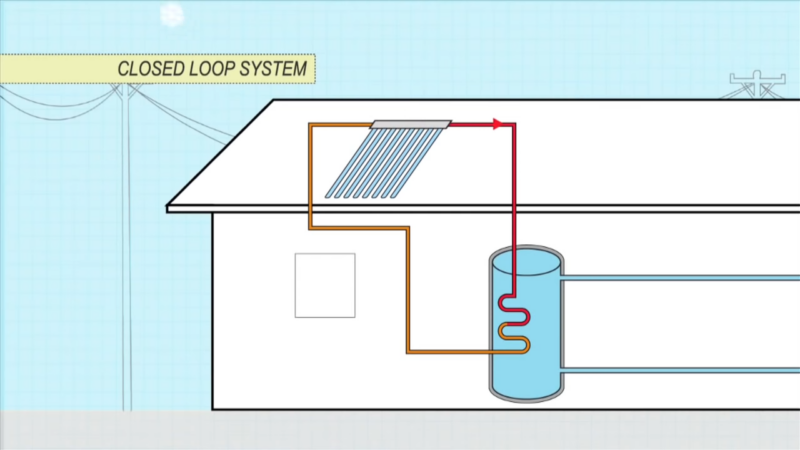

Instead of a circulating pump, the hot water would rise out of the waterfront into the top of the range boiler (large water tank). The colder water in the tank would fall out of the bottom of the range boiler (large water tank) and into the hot water front (small tank in the woodstove).

In this system, the water circulates all by itself through the process known as thermosiphon. Years ago this type of water heater would have been the primary or only water heater in the home

Today these are more commonly used to preheat well or municipal water before it enters the main water heater although they can easily supply enough hot water for a typical family during the cold months your woodstove is required.

Sample Hot Water Fronts

This hot water front (above) is made from a stainless plate (but could be regular steel or cast iron) and has 1 baffle to force water to travel more slowly and make surface contact with the hot surfaces.

This hot water front (above) is made from a stainless plate (but could be regular steel or cast iron) and has no baffles. Notice how the water travels from inlet to outlet making very little contact with the hot surfaces.

In the above illustrations is it obvious the more baffles you install in your hot water front the more hot water you can expect it to produce. However one is usually plenty. It gets very complicated to weld, the more baffles you install.

You MUST use pressure relief valves on the inlet and/or outlet tubing.

Other Wood Stove Hot Water Heating Systems

There is a relatively new product available online called the “Therma- Coil” (out of business) which is a small u-shaped coil made to insert into your wood stove and attach to your range boiler. They can be installed at any time by drilling two holes in your wood stove and connecting the plumbing.

If you wish to make your hot water coil only use rugged materials inside the firebox such as brass, steel, and stainless steel with threaded fittings. Do not use copper pipe with soldered fittings or copper tubing with a 180-degree bend.

Copper is too soft and unforgiving if the pipe were empty of water with a fire going. Soldered joints will simply unsolder themselves immediately if overheated.

The same rules apply when using a hot water front. You want the system to circulate without any pumps. Mount the U Shaped pipe horizontally as in the photo so there will be a top fitting and a bottom fitting.

The top fitting must be connected to brass, copper, steel, stainless steel, or some other metal piping and go to the top fitting on your water tank (range boiler).

The bottom of the U-shaped pipe will connect with metal piping to the fitting closest to the bottom of your tank. The closer to the bottom of the tank the fitting is, the more storage of hot water you will have. If your lowest fitting is 8 inches from the bottom of the tank, the bottom 8 inches of your tank will store no hot water.

We have no experience with them but they look reasonably well made and the concept is proven.

You MUST use pressure relief valves on the inlet and/or outlet tubing.

Brass Fittings Placed on Top of the Woodstove

Another slightly less efficient method of heating water with your wood stove is to make a maze of threaded brass or stainless steel pipe fittings and lay them on top of the wood stove if your wood stove has a flat top. You could also make a coil of soft copper tubing and set it on the top of the wood stove for the same effect.

Although this would not make as much hot water as a waterfront or loop of pipes inside the firebox, it will make a lot more than nothing and require no drilling or modification of your wood stove. This method of heating water would likely be one of the most insurance-friendly systems as you are not modifying your wood stove and you could easily remove it if your insurance company decides to visit for a home inspection.

You MUST use pressure relief valves on the inlet and/or outlet tubing.

Copper Coil Inside Your Stove Pipe

Another method of capturing your wood stove’s heat is to make a coil of copper tubing that is just small enough to fit inside your stove pipe. Usually, you would use 1/2″ (13mm) soft copper tubing for this project and you would increase your stove-pipe diameter to make up for the space taken by the copper tubing.

For example: If your wood stove’s manufacturer recommends a 5″ stove-pipe. you would use 6″ to keep the correct amount of draft for your wood stove.

BE SURE TO USE REFRIGERATION-TYPE COPPER TUBING AS IT IS THICK AND SOFT (MAKING IT EASIER TO COIL)

The biggest issue we have found using this system is the creosote that forms on the copper tubing because of the large difference in temperature between the water and the super heated air going up your chimney. All of the systems mentioned in this article will form creosote to a certain extent but the copper tubing in the stove pipe seems to be the worst.

EVEN WITH SOFT TUBING, IT IS A GOOD IDEA TO INVEST IN A TUBING BENDER OR FILL THE TUBING WITH SAND (LIKE SILICA SANDBLASTING SAND) BEFORE ATTEMPTING TO BEND TO AVOID KINKING THE TUBING!

Once a thick layer of creosote has formed it reduces the size of the stove pipe. The other issue is the system loses its effectiveness as the creosote acts like an insulator between the hot air and cold water.

You MUST use pressure relief valves on the inlet and/or outlet tubing.

4. Copper Coil Wrapped Around Your Stove Pipe

This is an example of a nice-looking installation of copper tubing wrapped around a 5-inch stove pipe and covered with a 6-inch stove pipe. The cold water enters the bottom and the hot water exits the top. The hot water tank is on the second floor.

The last option for making hot water with your stove is to capture the heat from the chimney by wrapping soft copper tubing around it or some other type of heat exchanger. For cosmetic reasons, you could add a larger stove pipe to hide the copper tubing.

BE SURE TO USE REFRIGERATION-TYPE COPPER TUBING AS IT IS THICK AND SOFT (MAKING IT EASIER TO COIL)

For example: If your stove pipe is 5″, you could install a 6″ over it. This will also act as a double-wall stove pipe.

If you decide to capture the heat from the stove pipe and the range boiler needs to be above the copper coil, you will either need to install it (range boiler) on the floor above or use a circulating pump.

EVEN WITH SOFT TUBING, IT IS A GOOD IDEA TO INVEST IN A TUBING BENDER OR FILL THE TUBING WITH SAND (LIKE SILICA SANDBLASTING SAND) BEFORE ATTEMPTING TO BEND TO AVOID KINKING THE TUBING!

Like the brass fittings on top of your woodstove this stove pipe system would probably be fine for most insurance companies. You have not modified your stove in any way.

This system should not cause any creosote and should not ever get hot enough to melt the copper tubing if the system was to run dry (without water).

You MUST use pressure relief valves on the inlet and/or outlet tubing.

Design Considerations for Circulation

As we are not using any pumps to circulate the water we must be very careful to ensure the following:

- The tank must be located higher than the wood stove

- The tank must be located very close to the wood stove to avoid long pipe runs

- The drain of the water heater must connect to the input of the hot water front or coil and be higher than it

- The hot water piping coming out of the hot water front, coil, or U shape heater must go into the top-of-the-range boiler

- All piping must be sloped at least 12″ for every 24″ of pipe run (45°)

- The larger the piping the better (use 3/4″ or 1″)

- Avoid 90-degree elbows or other restrictive fittings as much as possible

Safety considerations

- ONLY USE METAL PIPING (copper, black iron, steel, stainless steel, galvanized). Never use pex, abs, or pvc from the stove to the tank.

- Insurance companies will never like any of these ideas

- Always use at least one pressure relief valve (preferably two) between the woodstove and the tank

- Use temperature/pressure relief valves to make the system safer.

- NEVER INSTALL VALVES BETWEEN THE STOVE AND HOT WATER TANK

The best arrangement would be to have the range boiler on the floor above the floor the wood stove is on. That would allow for excellent circulation.

Circulation Pumps

If your wood stove and water heater are a long distance apart or you are unable to make the system circulate by gravity, you can always use a circulating pump to move the hot water back and forth. If you go the circulating pump route, resist the temptation to purchase a standard “off-the-shelf” pump.

As you have to generate the electricity required for the pump you will need a super high-efficiency pump such as an Ivan Labs EL SID DC pump or a Laing LHB08100086 E1-BCTNRN1W-06 EcoCirc Circulator AC pump.

If you use a pump you WILL need a thermostatic control to turn the pump on and off. You have 3 options:

1. Use a thermal (low limit) snap switch

A thermal snap switch is a very primitive yet reliable way to operate your hot water circulating pump. They are super cheap so buy a few spares. They use a bimetallic strip much like your thermostat on your electric baseboard heaters to make contact when your room becomes cool except it operates in reverse.

As the wood stove (or your water jacket/loop) heats up, the switch turns the pump on, and when the temperature lowers the contracts open, turning off the pump. I would recommend a turn-on temperature of about 100 F if mounted to a wood stove as the wood stove will take longer to heat up than in an internal loop or hot water front.

Here are some more examples of thermal snap switches.

2. Use a boiler aquastat (water jacket or external)

The most reliable ( and more expensive) method of turning the circulating pump on and off is the aquastat that has been used in hot water boilers for many decades. As the water heats up in a typical gas, wood, or oil hot water boiler, the aquastat (a thermostat for water…hence the AQUA) closes the circuit to start the circulating pump. As the boiler cools down, the pump shuts off. These are robust and usually outlast a hot water boiler.

The second bonus is they are completely adjustable for on and off temperature. Something to remember…most aquastats are built to turn an oil or gas-powered burner which operates exactly the opposite of what we need. You are looking for a reverse acting (or low limit) aqua-stat unless you know how to convert a “normal” one to reverse acting. Honeywell is a common name in aqua-stats in North America.

They come in external models that come be mounted to your wood stove or external piping using magnets in some cases or hose clamps in older models.

They also come in water jacket models or internal models where the temperature probe is actually in contact with the water of your water jacket if applicable. If you can find an old boiler at a scrap yard you will be able to find a suitable aquastat for little to no money. They almost last forever if kept dry.

3. Use a solar hot water temperature controller

These are awesome while less reliable and bulletproof (in my opinion) than the above-mentioned items. Google “solar hot water temperature controllers” for more info. There are many.

Do not buy any circulating pump before reading this.

WARNING! Please read this first!!!

When water is heated, it expands. The cold water that enters the system is heated to 120-180 degrees f and expands slightly. This expansion is usually handled well by the same expansion tank that keeps the pressure constant in your water system. This is how a “normal” water heater doesn’t always build pressure or blow the pressure valve.

However, if that hot water turns into steam it will expand 1600 times. That will not be handled by the pressure tank. Instead, the range boiler, water front, or piping will explode. Many people have been killed by this during the past century.

Always have a pressure relief valve between the range boiler and the water front and preferably two of them (one on each line). Steam is very dangerous.

- Adjustable Hot Water Pressure Relief Valve with 1/2″ or 3/4″ Outlet

- Fixed Hot Water Pressure Relief Valve with 3/4″ Outlet

- Adjustable Hot Water Pressure Relief Valve with 1/2″ Outlet

- Fixed Hot Water Pressure Relief Valve with 3/4″ Outlet

Temperature and Pressure Relief Valves

- Fixed Pressure and Temperature Relief Valve with 1/2″ Outlet

- Fixed Pressure and Temperature Relief Valve with 3/4″ Outlet

- Adjustable Pressure and Fixed Temperature Relief Valve with 1/2″ Outlet

Do not install any valve (open/close) on either pipe between the hot water front and the range boiler.

You are just asking for trouble by doing this. Someone (maybe a child) will close the valves turning your water heater into a bomb!

A few decades ago the solution to not having a pressure relief valve was like this…

If your fire is lit and you hear bubbling in the system, the water is likely starting to boil. The correction is simple. Just open a hot water tap (or a few of them) and dump that excess hot water. Do not leave a hot water range boiler unattended…ever!

Our forefathers did not have pressure relief valves so they had to be very aware of steam production. Many died from these units as they are a bomb waiting to blow.

Try this method for making cheap hot water and please share (leave a comment/send us an email) to let us know how it works for you!